Customized applications for Tube & Wire, Food & Beverage, Cosmetics & Pharmaceutical

We represent, install and support the full range of KBA-Metronic German-engineered Coding & Marking systems in Egypt. Our mission is to provide our valuable customer with the right coding system that suits his production environment.

- High Speed Feeding Solutions for Offline Sleeve & Cartoon Packaging.

- Complete “Track & Trace” Application Including 2D Bulk Reading,Labeling & Visual Inspection

- Offline Coding Systems

- Industrial Inkjet Printers

- Thermal Transfer Printers

- Hot Foil Printers

- Rental Service

- Consumables

- Broad Range of Inks, Solvents , Ribbons and Parts (Ex-Stock)

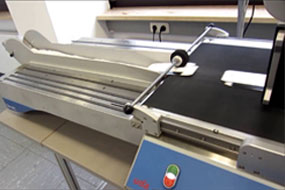

FORMAXX (i) Sleeve and Carton Coder

The (i) model, also has an intermittent mode which enables the feeder to stop briefly as the product moves under the print head. This makes it suitable for hot foil and thermal transfer printing as well as for inkjet and thermal inkjet coding.

- 'Friction Feeder' for coding and labelling sleeves, cartons, backing cards, crash-lock boxes and pouches

- Simple to adjust for a wide range of packaging types and sizes

- Strong belt-grip ensures accurate positioning each time

- Option for 'intermittent' mode makes is suitable for hot foil and thermal transfer printing (as well as inkjet and thermal inkjet)

- Supplied with your choice of printer and/or label applicator

- Can be supplied with camera system for post-print verification

- Low-maintenance, simple operation

- High-quality build for durability and reliability

- Speed: up to 600 packs per minute

FORMAXX (c) Sleeve and Carton Coder

(continuous) operation with belt with broad belt conveyor

- Material width:min. 30 mm, max. 450 mm min. 64 mm, max. 368 mm

- Material length:min. 60 mm, max. 500 mm min. 45 mm, 430 mm (500 mm optional)

- Material thickness:min. 100 g/m2, max. 7.5 mm min. 100 g/m2, max. 5 mm

- Speed:infinitely variable to max. 90 m/min. infinitely variable to max. 90 m/min.

- Output:up to 1.000 pcs./min. up to 1.000 pcs./min.

- Operation:operation terminal (polyglot) with graphic display and touch screen.

- Mech. construction:corrosion free: VA/anodised aluminium, most suitable e.g. for the pharmaceutical industry.

- Dimension:1300 (+ 626 stacker) x 680 x 362 mm, L x W x H

- Weight: ca. 107 kgs (without coding equipment)

Power connection: 230 V (115 V) + 10 % tolerance, according to IEC38, approx. 700 VA (without coding system) Standard for both systems:

- Brushless Servo Drive

- Display For Settings And Status

- encoder for speed settings

- print signals for 2 coding- / camera systems

- feeder and delivery

Optional for both systems:

- indicator light

- frames for coding systems

- connectors for coding systems

- print detection, camera systems

- shuffle board

- print signals for 4 coding- / camera systems

Shingling Conveyor

The variable speed shingling conveyor is available as an additional module for the udaFORMAXX sleeve and carton feeder.

The conveyor neatly queues up batches of your sleeves or cartons, making it even easier for operators to collect them ready for packing. Because it can hold higher volumes than the standard ‘magazine’, operators can load more sleeves each time – dramatically increasing throughput.

Collation speed is controlled by the feeding and printing speed of the udaFORMAXX itself. The shingling conveyor is a modular system that can be easily retrofitted to existing udaFORMAXX sleeve and carton feeders.

Inkjet on Sliding Table

- Sliding table creates movement for inkjet print

- Print high quality codes and marks

- Non- contact printing suitable for a wide range of substrates

- Raise or lower print head height for different pack sizes

alphaJET mondo

Printing

- Up to 5 lines

- 32 pixels

- Font size 2 - 15 mm

- Max. speed: 385 m/min

- Text composition: automatic time and date functions, consecutive numbering, bar codes, logos etc.; TrueType fonts, as well as a large selection of other fonts

Operation

- 8.4" TFT touch screen display with an intuitive user interface

- Solvent resistant display

- Graphic User Interface (WYSIWYG)

- User profile management system

- Easy changeover of languages

alphaJET into

Printing

- Up to 5 lines

- 32 pixels

- Type height 0,8 - 15 mm

- Speed up to 460 m/min (5 x 5 Matrix)

- Text composition: automatic time and date functions, numbering (with autostop), textlist function, consecutive numbering, Barcodes, Data Matrix Codes, Logos etc.; True Type Fonts, optional customized software

Operation

- 10.4" TFT touch screen display with an intuitive user interface

- Solvent resistant display

- Graphic User Interface (WYSIWYG)

- user profile manager

- language selection

alphaJET evo

Printing

- Up to 8 lines

- 48 pixels

- Type height 0,8 - 15 mm

- Speed: max. 460 m/min

- Text composition: automatic time and date functions, numbering (with autostop), textlist function, consecutive numbering, Barcodes, Data Matrix Codes, Logos etc.; True Type Fonts, optional customized software.

Operation

- flexible 10,4“ TFT-Touchscreen Display with user-friendly interface

- Solvent resistant display

- Graphic User Interface (WYSIWYG)

- user profile manager

- language selection

alphaJET tempo

Printing

- up to 4 lines

- 24 Pixel

- Type height 0,8 - 15 mm

- Speed: max. 600 m/min

- Text composition: automatic time and date functions, numbering (with autostop), textlist function, consecutive numbering, Barcodes, Data Matrix Codes, Logos etc.; True Type Fonts, optional customized software.

Operation

- flexible 10,4“ TFT-Touchscreen Display with user-friendly interface

- Solvent resistant display

- Graphic User Interface (WYSIWYG)

- user profile manager

- language selection

alphaJET pico Micro Print

The alphaJET pico is the best choice for micro-print with excellent readability. Ideal when you have to print a lot of information in the narrowest spaces. Uniform replica watches sale droplet formation gives you an especially clear code.

The alphaJET pico is widely used in the pharmaceutical, healthcare, cosmetics and cable manufacturing industries.

- Uniform droplet formation ensures that tiny fonts can be printed with excellent readability

- Prints up to 5 lines

- Ideal for printing data matrix codes and bar codes on restricted print areas

- IP65 rating and solvent recovery as standard

- Easy operation with icon-driven touchscreen

- Advanced user profile settings

- Suitable for diverse range of standard and specialist inks (including UV readable)

- Heated print head

- Automatic nozzle shutter

betaJET Thermal Inkjet

- Fast, consistent printing with excellent code quality

- Reliable and maintenance free

- Intelligent, icon-driven user interface

- Suitable for porous and non-porous materials

- Print head configuration for up to four print heads at print speeds of up to 120 m/min

- Print height from 12.7mm to 50.8mm

- Print up to 600dpi resolution of horizontal print, vertical print, bar codes, 2D data matrix codes and logos

ttPRINT Inline

- Print speed up to 800 mm/s

- Print area: continuous mode 53 / 107 / 128 x 3000 mm, intermittent mode 53 / 107 / 128 x max. 75 mm

- Resolution 300 dpi

- Print memory 16 MB

- Memory Card – Compact Flash 128, 256, 512 oder 1024 MB

- Available with IP65 control unit and 'cleaning cassette'

ttPRINT ML

- Print head: 53 / 107 / 128 mm

- Print length: 140 - 630 mm

- Ribbon-saving function

- High speed capacity

- Packaging machinery integration

- Quick ribbon change

- Easy operation

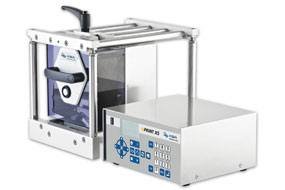

ttPRINT XS

- Compact design

- High resolution print

- Print area of up to 53 x 40 mm

- Ribbon-save

- Optional touchscreen control

hpdSYSTEM vario

- Up to 1000 prints/minute

- Print area 30mm x 50mm

- Technically advanced, yet easy to operate

- Set cassette up in a matter of seconds

- Print sequence control

- Warning system for foil end

- Exchange cassette minimizes setup time

- Infinitely adjustable foil feed, temperature and printing time

- Very straightforward to operate and maintain

hpdSYSTEM nano

- Up to 1000 prints/minute

- Print area 30mm x 50mm

- Technically advanced, yet easy to operate

- Set cassette up in a matter of seconds

- Print sequence control

- Warning system for foil end

- Exchange cassette minimizes setup time

- Infinitely adjustable foil feed, temperature and printing time

- Very straightforward to operate and maintain

hpdSYSTEM magno

- Wide area hot foil coder

- Print area 50mm x 80mm

- Edge-mounted to print to edge of product

- Clear marks that survive heat, moisture and other challenges in the production process

- Codes that resist transfer on a coiled spool

- High-speed coding for fast rewind speeds

- Bright, legible codes that stand out on dark and coloured surfaces

- Easy-to-use touchscreen for quick message changeover

- High adhesion inks suitable for most sheathed cable variants, including PVC, PVC-LSOH, HDPE, HFFR and XLPE